Fields, Methods and Techniques

Fields

The research and technology transfer and knowledge fields of LERMA are the Strength of Materials and the Structures in the broadest sense. It specifies in the analysis, design, calculation and optimization of resistive elements, structural components and structures: especially on complex behaviours, instability phenomena, lightweight structures, experimental measures and verifications: and always looking for to deepen the knowledge and the innovation of concepts and applications.

The areas where LERMA has collaborated with companies and institutions are varied: light and heavyweight machinery, vehicles, racks, construction, maintenance, measurement, biomechanics, bioengineering, renewable energies, nuclear energy, etc.

The areas where LERMA has collaborated with companies and institutions are varied: light and heavyweight machinery, vehicles, racks, construction, maintenance, measurement, biomechanics, bioengineering, renewable energies, nuclear energy, etc.

Methods and techniques

- Classic analytical methods

- Linear elasticity

- Strength of materials

- Structure theory

- Numerical simulation (method of finite elements)

- Linear analysis

- Analysis without geometric and material nonlinearities

- Dynamic analysis

- Materials testing

- Static tests (tensile, compression, bending, etc.)

- Fatigue tests

- Impact tests

- Static, cyclic and fatigue tests

- Control by displacement, strain or force

- Component testing

- Structural elements

- Facilities elements

- Automotive components

- Parts and components

- Experimental analysis of stresses and strains

- Strain gauge

- Electrical measurement of mechanical parameters (force, torque, pressure, displacement, rotation, etc.)

Facilities and equipment

Servo-hydraulic machine, computer controlled (MTS) |

|

Multifunction Test Bench

|

|

INSTRON

|

|

Load frame

|

|

Under longitudinal loads

|

|

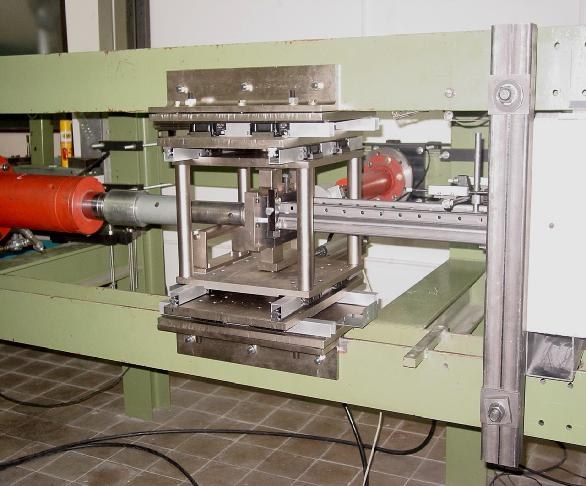

Biaxial test bench

|

|

Data acquisition systems

|

|

HBM Amplifiers

|

|

HBM multichannel system

|

|

Sensors for strain measurement

|

|

Sensor offsets

|

|

Computational centre

|

|

Share: